Benefits of CNC Machines in Architectural Work

CNC machines have been in the limelight for more than 50 years, but the modern sophistication of these tools is pretty recent. You can carve out almost any material including wood, plastic, metal, foam, and more with unmatchable precision and almost without the use of any human help.

A CNC machine is an integral part of the manufacturing process, and most operations in building physical parts are done through one or another CNC machine. It is not limited by one industry type, as almost all fields of work require some kind of manufacturing process, and CNC machines are there to sort it out. Architecture is one such field that has benefited a lot from automated computer numerically controlled machines.

From a digital design to a 3D model, CNC machines are used to bring architectural work to life. Keep reading to know how CNC Machines form a focal part of the world of modern architecture.

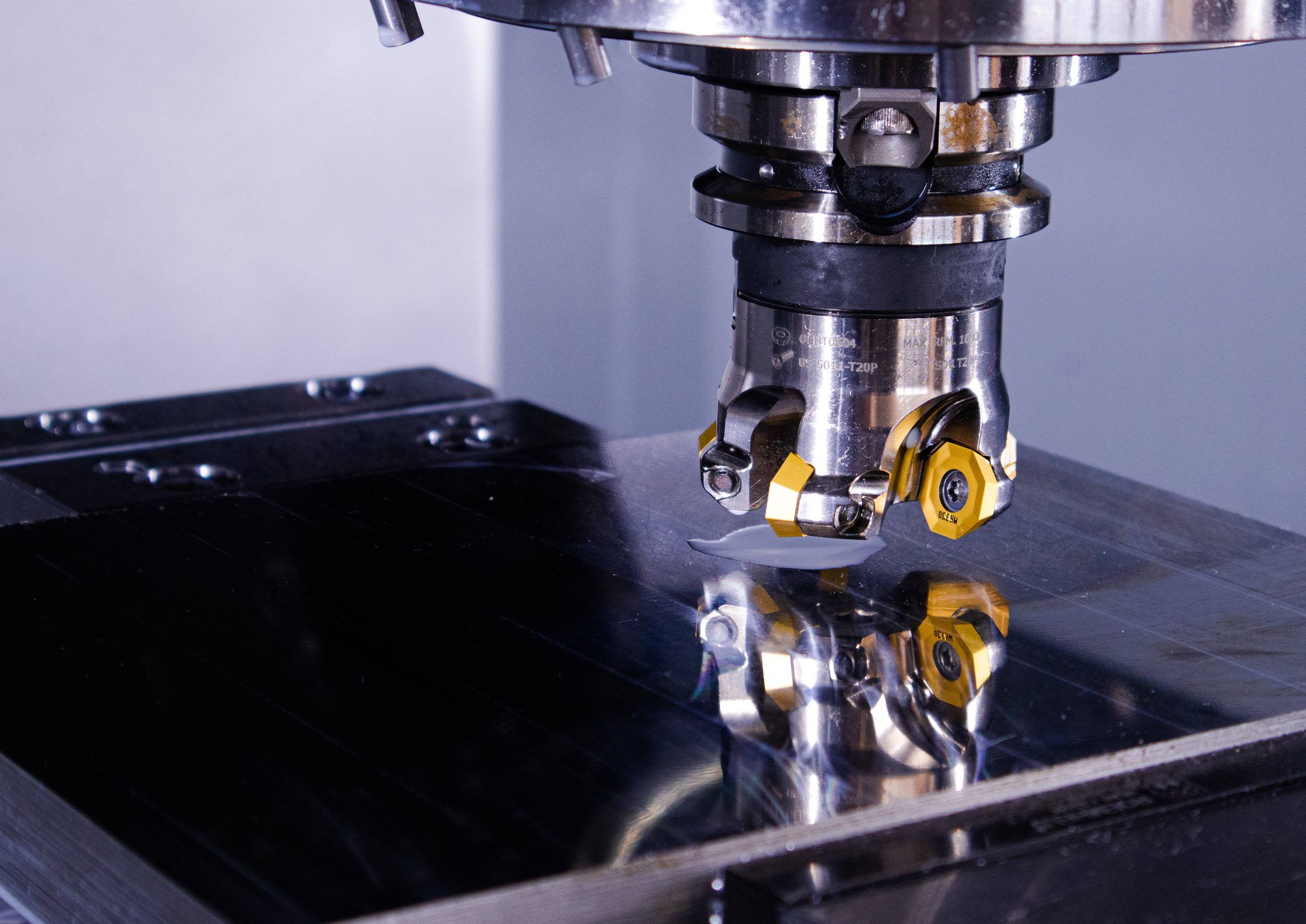

There are different types of CNC machines used for the manufacturing process, including vertical and horizontal milling machines, routers, plasma cutting machines, lathe machines, grinders, and more.

With these tools, the architecture world can juice out highly beneficial facets of designing, modeling, and manufacturing processes. CNC machines make work faster, safer, more efficient, more precise, and they work with a variety of options.

If you are suspended in the middle of deciding to use a CNC machine, consider it a necessity. If you don’t believe this, read on to find all the advantages your business will forego if CNC machines are not integrated with architectural work right away. Let’s begin.

image © unsplash

Seamless Building of Models

You might think that CNC machines are of no use to you in the design process as they are manufacturing tools. But these machines can also help you build your design prototype as a real-life model.

Complete the design process, as usual, using CAD software. Once the prototype is ready, program an algorithm for the CNC machine and feed it in. The machine will build your model with the material of your choice, and a precise prototype will be ready soon enough.

This will make it easier for the architects, builders, and other members of the team to understand the requirements of the design so a better image can be projected in the real, physical building.

Advanced Capability

If you pair the CNC machine with high-power design software, the resultant product will be one that could not be matched up to. No matter how talented an engineer is working on the project, the efficiency of a CNC machine to build stuff far outweighs any manual designing and building tools.

You can build any type of design with a CNC machine. If you can produce it on the screen of your computer, you can touch it in real life as well.

Variety of Materials

The architectural prototype can be built with several different materials, owing to the capability of a CNC machine to work with almost all kinds of materials such as aluminum, gold, silver, brass, plastic, wood, and more. You can get your design ready in any material you want, so the clients will have a better idea of what the final product will look like with the chosen material.

Zero Human Errors

When a machine such as a CNC machine builds a prototype, you can be sure that it will look exactly like how you designed it digitally. This is because mechanization removes any human errors if there are any. In other words, human inconsistencies are eliminated.

There are certain fields such as architecture, automotive, and aerospace industries where precise measurements in the products are extremely important. You can feed in the exact dimensions of the product, and you will have parts of the product manufactured with precise measurements and no errors.

Improved Speed

A machine will work faster than a manual process of accomplishing outcomes. In the case of CNC machines, you might not even need an operator to control them. All you need are the instructions for the machines to finish a task. Add the algorithm into the machine, provide the raw material to work on, and you can see the magic happen with little to no input from human beings.

Decreased Amount of Used Resources

If you use CNC machines for prototyping and creating products and models, you can significantly eliminate wasted material that would be a common sight otherwise. A CNC machine works according to precise measurements, and it will only use the needed material to build the resultant product. So, by using a CNC machine, you can expect a large reduction in the resources your business requires, thereby saving a lot of money.

Uniform Measurements

By choosing a CNC machine over other traditional manufacturing machines, you ensure that the products have uniform measurements. If you want to build more than one prototype of the same measure, a CNC machine will produce as many products as you want, all of the same size and shape.

Uniform products will help the team members and workers stay unified over a project’s requirements and evade any miscommunication. You can just enter the instructional code, and the machine will be good to go.

Comprehensible Software

CNC machines are easy to operate. You don’t need high-end engineers to complete the tasks. You can simply update the machine’s installed software. There is virtual software training available for the operator where the trainee goes through a game to practice using the CNC machine online.

The designer can use the software to bring a simulation of the design to life and work with it before producing a prototype. In some cases, the designer may not even need to build an actual prototype as the simulation will be enough. This works well in reducing costs and saving time immensely.

Flexibility in the Revisions of Products

This is one area that enhances the importance of CNC machines for architectural work. Revisions and changes are a big part of prototyping. If you suddenly remember or notice at the last minute that a small design change is needed in the product or some fixing is needed with the design, redoing the whole prototype with other methods can leave you with wasted time and obsolete parts sitting around.

With a CNC machine for prototyping, you can insert changes in between. You can add in the instructions for the additional detail so the product won’t be wasted. You can also design similar prototypes with slight changes without having to overdo the whole product. Some changes in the code and the prototype will be molded according to your design.

Conclusion

As the world is advancing and new technologies are being invented, it plays in the favor of the businesses to incorporate those tech innovations into their systems for efficient outcomes. The contemporary CNC machines are an essential tool for the manufacturing process of your products. Looking at the long run and the big picture, you will notice the increased amount of time, effort, and cost saved by using CNC machines for architectural work.

Remember to do your research before investing in any CNC machine. Not all of them are made for every type of work. Define your outcomes clearly before digging in.

Which CNC machine do you use to make your prototyping process seamless?

Author: Bailey Hudson

cover image © pexels